Concrete forming is a critical aspect of construction, influencing the structural integrity and aesthetics of the final product. In Australia, one material that stands out for its versatility and reliability is Formply. This unique product offers a range of benefits tailored for the unique demands of the Australian construction industry. In this article, we will explore the characteristics, advantages, and practical applications of Formply, as well as provide tips for its effective use in concrete forming.

Understanding Formply: An Overview

Formply is widely available across Australia, with various suppliers offering a comprehensive selection, from small retail outlets to large industrial supply companies. This vast availability ensures that builders can source the right quantity and grade of formply Australia for their projects efficiently.

What is Formply?

Formply, or formwork plywood, is specifically designed for use in the construction industry. It is manufactured from a combination of durable hardwood or softwood veneers, bonded with a water-resistant adhesive to create a robust panel. This construction technique ensures that Formply maintains its integrity even under substantial stress and moisture conditions, making it ideal for casting concrete.

Formply is typically treated with a special film or resin overlay, which adds to its durability and creates a smoother surface finish. This film not only enhances the panel’s lifespan but also minimizes the risk of surface blemishes on the concrete, ensuring a high-quality result each time. The treatment process can also include anti-slip properties, which can be beneficial for workers on-site, enhancing safety during the construction phase.

The Unique Characteristics of Formply

One of the standout features of Formply is its excellent structural properties. Its strength-to-weight ratio allows for easy handling and installation without compromising on performance. Additionally, Class 3, Class 4, and Class 5 ratings distinguish different Formply grades based on use conditions, allowing builders to select the right panel for their specific project needs. This classification system helps contractors make informed decisions, ensuring that they choose a product that aligns with the demands of their specific construction environment.

Another defining characteristic of Formply is its water resistance. Unlike standard plywood, the adhesive bonding in Formply is engineered to withstand contact with water, ensuring that it can be reused multiple times without warping or degrading. This longevity contributes significantly to its appeal in both residential and commercial construction. Moreover, the ability to withstand harsh weather conditions makes Formply a preferred choice for projects in regions with high humidity or rainfall, where other materials might fail. The versatility of Formply extends beyond just concrete casting; it can also be utilized in various applications such as flooring, wall sheathing, and even temporary structures, showcasing its adaptability in the construction landscape.

The Advantages of Formply for Concrete Forming

Durability and Strength of Formply

Durability is undoubtedly one of the foremost advantages of Formply. This material can endure heavy loads and the stresses of concrete pouring without failure. As it undergoes numerous cycles of wetting and drying, Formply remains dimensionally stable, thereby contributing to the structural integrity of the concrete it supports.

The strength of Formply not only enhances safety at construction sites but also ensures that labour can proceed without frequent downtime due to equipment failure or repair. This reliability ultimately translates to more efficient project timelines and reduced costs over the life of the project. Additionally, the robust nature of Formply allows it to withstand the harsh conditions often encountered on construction sites, such as extreme temperatures and exposure to chemicals, which can degrade other materials. This resilience further solidifies its position as a preferred choice among contractors looking for dependable formwork solutions.

Cost-Effectiveness of Using Formply

Formply’s initial cost may be higher compared to traditional plywood; however, its longevity and reusability make it a cost-effective option in the long run. Projects that require extensive formwork will benefit from reduced waste and maintenance costs over time due to the durable nature of Formply.

Furthermore, Formply can be used in various applications, which minimizes the need for multiple materials. The versatility of Formply means that it can be adapted to meet different requirements, leading to further cost savings in material procurement and management. For instance, it can be employed in both vertical and horizontal forming applications, making it suitable for a wide range of construction projects, from residential buildings to large-scale infrastructure. This adaptability not only streamlines the construction process but also allows for better inventory management, as fewer types of materials need to be stored and transported.

Environmental Impact of Formply

In an age where environmental awareness is paramount, the eco-friendly characteristics of Formply are noteworthy. Many manufacturers source their timber from sustainably managed forests, which helps to reduce the environmental impact associated with construction materials. Find more about sustainably on https://www.sustain.ucla.edu/what-is-sustainability/

Moreover, Formply’s durability means that it does not need frequent replacements, leading to less waste generation. Reusing Formply for multiple cycles contributes to a more sustainable approach to concrete forming, making it an ideal choice for environmentally conscious builders. In addition, the production processes for Formply often incorporate advanced technologies that minimize energy consumption and reduce emissions, further enhancing its green credentials. By choosing Formply, construction companies not only meet their project requirements but also align themselves with global sustainability goals, appealing to clients who prioritize eco-friendly practices in their projects.

Formply in the Australian Context

Australian Standards for Formply

In Australia, strict standards govern the manufacturing and quality of Formply. The standard AS 6669 outlines the specifications for formwork plywood, ensuring that products are produced with uniformity and quality in mind. These regulations help builders select the right type of Formply suited for their specific construction needs.

Understanding these standards is essential for contractors who wish to ensure compliance and quality in their projects. Utilizing Formply that adheres to Australian standards not only ensures a level of quality but also aids in meeting regulatory requirements upheld within the industry. Furthermore, adherence to these standards can significantly reduce the risk of structural failures and enhance the longevity of the construction, as Formply designed to meet these specifications is tested for durability and performance under various environmental conditions.

Availability and Accessibility of Formply in Australia

Additionally, the growing popularity of Formply has led to an increase in accessibility; suppliers often stock a range of sizes and thicknesses to cater to diverse construction requirements. Accessibility allows contractors and builders to complete projects without unnecessary delays due to material shortages. Many suppliers also provide delivery services, further enhancing convenience for builders who may be working on multiple sites or require large quantities of Formply. The competitive market has also driven innovations in product offerings, with some suppliers beginning to offer eco-friendly options made from sustainably sourced timber, appealing to the growing demand for environmentally responsible building materials.

Practical Applications of Formply in Concrete Forming

Residential Construction Applications

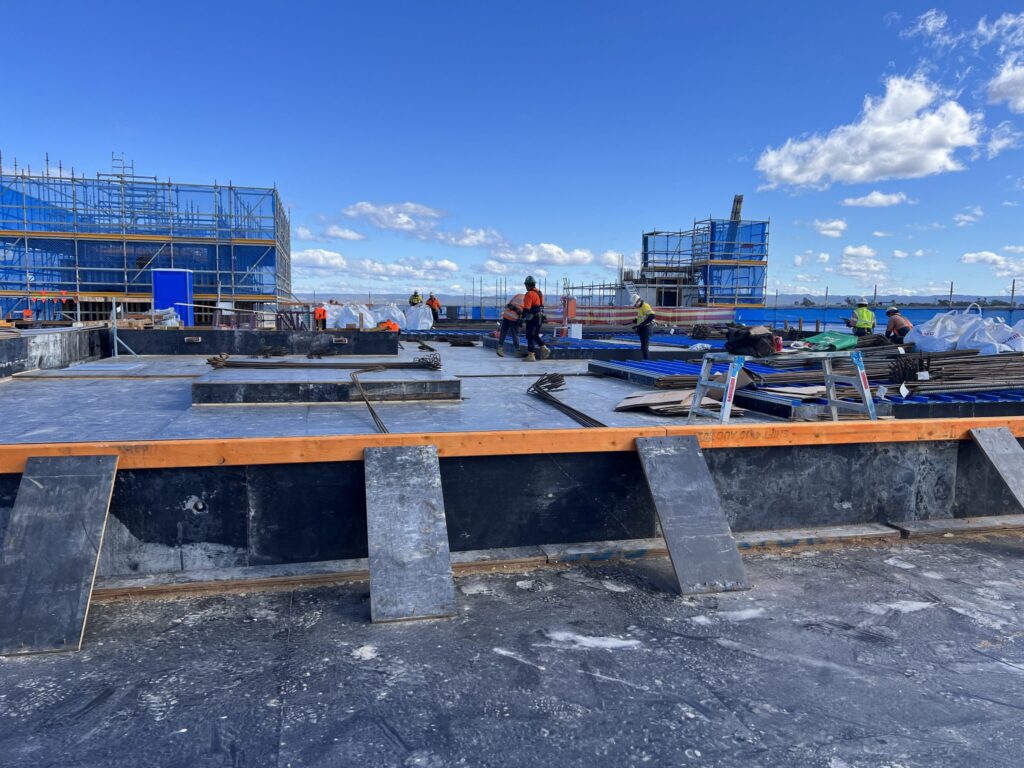

In residential construction, Formply is primarily deployed for foundations, slabs, and walls. Its ability to provide a smooth surface finish is crucial for projects requiring high aesthetic standards. For example, when constructing decorative concrete features like driveways or patios, the quality of the formwork can directly affect the final appearance.

Moreover, Formply can be used in creating bespoke architectural details for residential homes, including custom shapes like columns and arches, where precision and strength are required. This versatility makes it a favorite among builders focusing on custom home projects. The lightweight nature of Formply also facilitates easier handling and installation, allowing builders to work more efficiently without compromising on quality. Additionally, the material can be easily cut and shaped on-site, enabling quick adaptations to design changes, which is often a necessity in residential projects where homeowners may want to make last-minute adjustments. To read more about precision click here.

Commercial Construction Applications

Commercial projects benefit significantly from the strength and durability of Formply. High-rise buildings, parking structures, and commercial slabs often utilize Formply to ensure the safety and longevity of the structure. Given the larger scope of these projects, the material’s reusability becomes especially advantageous.

Additionally, Formply’s resistance to moisture and wear makes it ideal for use in environments subject to harsh conditions, such as exposed outdoor slabs and retaining walls. This adaptability ensures that commercial developers can trust Formply for a multitude of concrete forming needs. Furthermore, the use of Formply can lead to significant cost savings over time due to its durability and the reduced need for frequent replacements. In large-scale commercial applications, this translates to lower overall project costs and minimized downtime, which is critical in maintaining project schedules. The material’s compatibility with various concrete mixes also allows for enhanced performance in diverse applications, ensuring that structural integrity is never compromised, regardless of the specific demands of the project.

Tips for Using Formply in Concrete Forming

Proper Handling and Storage of Formply

To maximize the benefits of Formply, proper handling is critical. Always lift Formply panels carefully to prevent any damage. Avoid dragging them across abrasive surfaces that may scratch or mar the edges, as this can affect their fit and seal during use.

Additionally, when storing Formply, ensure that the panels are kept flat and stacked evenly. Protect them from direct exposure to elements and excessive moisture to maintain their integrity. Appropriate storage can significantly extend the lifespan of Formply and reduce the need for replacement. It’s also advisable to store the panels in a climate-controlled environment if possible, as extreme temperatures can warp the material, compromising its effectiveness in forming applications.

Best Practices for Formply Use in Concrete Forming

When using Formply for concrete forming, consider incorporating a few best practices to enhance performance. Always inspect the panels for defects or damage before use, as this can impact the final outcome of your concrete works.

Another essential practice is to apply a release agent before pouring concrete on Formply surfaces. This will aid in the easy removal of the formwork once the concrete has set, thus preserving the surface quality of both the Formply and the concrete. Furthermore, using a high-quality release agent can also prevent concrete from adhering to the Formply, ensuring a smoother finish and reducing the risk of surface imperfections. Following these best practices ensures that you achieve the best results from your Formply applications.

Moreover, consider the thickness of the Formply being used, as this can affect the structural integrity of the formed concrete. Thicker panels can provide better support for larger pours, while thinner panels may be more suitable for smaller, less demanding applications. Understanding the specific requirements of your project will allow you to select the appropriate Formply thickness, optimizing both performance and cost-efficiency. Additionally, always ensure that the panels are securely fastened and braced during the pouring process to prevent any movement that could lead to misalignment or defects in the final concrete structure.

Read about formwork plywood at: Choosing the Right Formwork Plywood for Your Construction Project